Intertech is a professional mold design, molding design, molding design,injection mold design engineering,mould engineering services Supplier. Find more mold design, molding design, plastic mould design,mould engineering services information here or contact us for full service.

Intertch provides mold design for customers.

We mainly use Pro-E, Solidworks software for 3D (.igs or .stp format) AutoCad for 2D (.dwg)

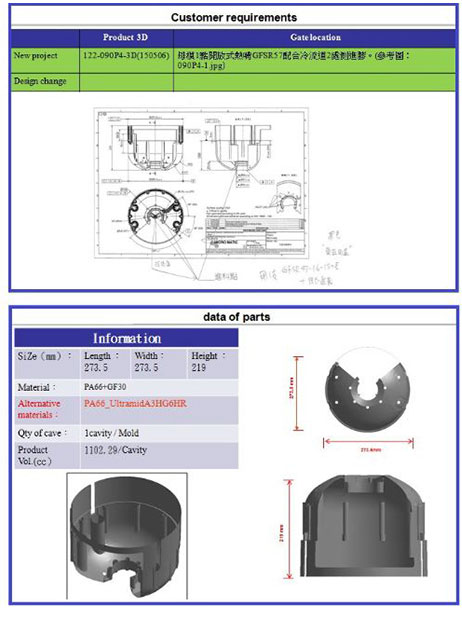

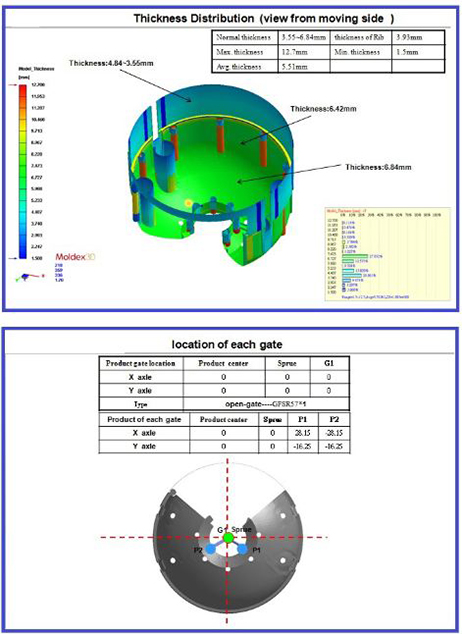

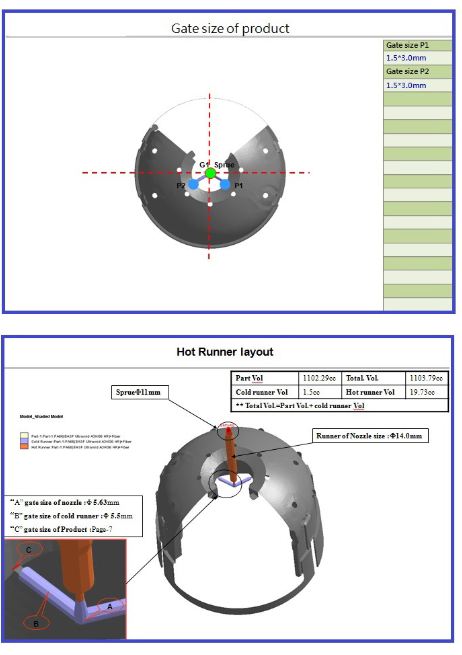

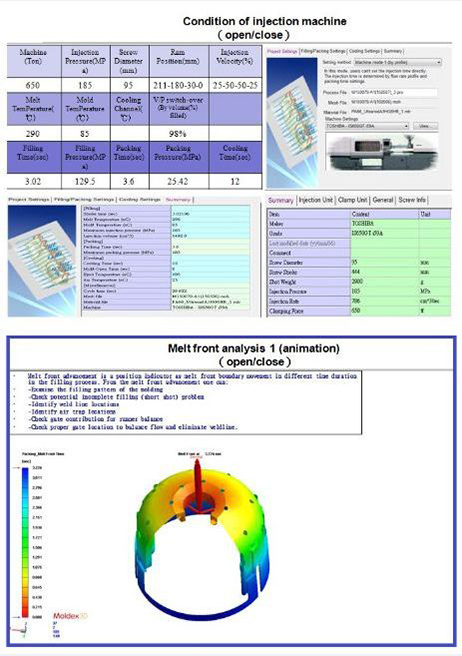

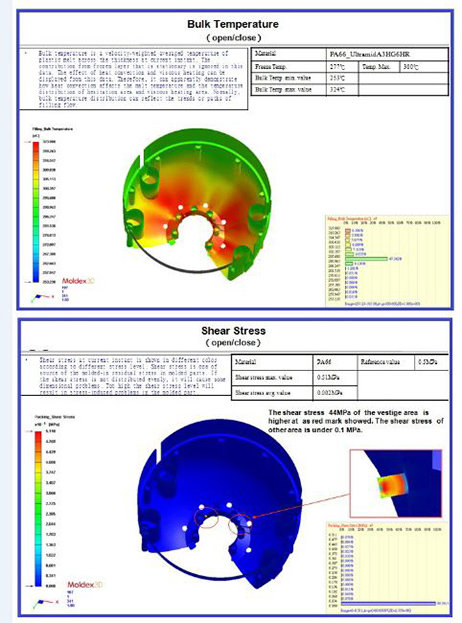

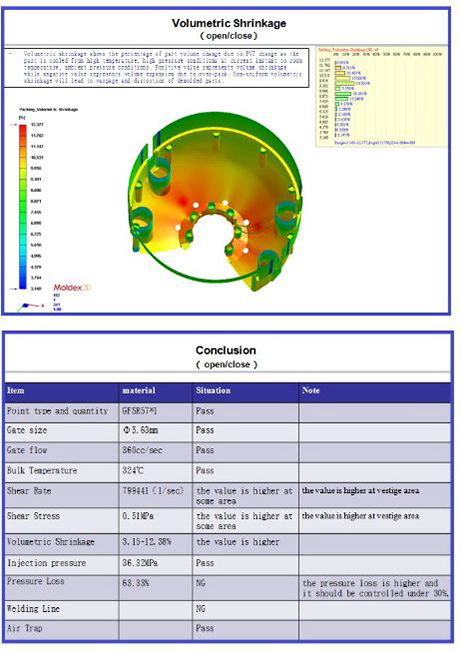

Up to customer’s requirement, we provide the custom mold flow analysis service. Before making the mold design, through the mold flow analysis, customer can optimize their parts design by checking the material filling, deformation, shrinkage, welding line, temperature, shear stress, hot runner layout…etc to de-bug the parts design mistake, to simplify the manufacturing process and to raise up the positive productivity rate. The following are some examples…of our mold flow analysis service contents.

Product Highlight:

Plastic materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30% |

Other materials: | Plastic |

Quality: | RoHS and SGS standard |

Feature: | Non marking and Non flash |

Size: | According to your drawing |

Color, Quantity, Unit price, Tooling cost, Tooling size: | To be discussed |

Mold structure: | Injection Mould, Plastic Mold, Overmould, 2k mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,…etc. |

Mould Base: | HASCO standard, European standard, World standard |

Mould Base Material: | LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

Surface Finish: | Texture (MT standard), high gloss polishing |

Finish: | Mirror finish etc. |

Cavity / Core steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

Cavity: | Single cavity, Muti Cavity, based on customer’s requirement. |

Hot / Cold Runner: | HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand…etc. |

Mould Life: | 1,000 to 1,000,000 shots (according to your working environment) |

Design & Program Softwares: | CAD, CAM, CAE, Pro-E, Solid works…etc. |

Equipments: | High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available. |

Package: | Standard exported wooden box packed, fumigation process (upon required) |

Mold building lead time: | T1, 20~50 days, parts measurement report (upon required). |

Annual production: | 250 sets of mold |

We produce many kind of different molds, if you are interested to our other products.

Please visit our company website!

www.taiwanmoldmaker.com

www.intertech.net.tw

Our Main Products:

Injection Mold, Silicone Molding, Rubber Mold, Silicone molding, PC High-Gloss Plastic Mold, Die Casting Mold, Silicone Mold, Silicone Rubber Mold, Liquid Silicone Rubber , Cosmetic Packaging Mold, Medical Products Mold, Engineering Plastic Molds, Home Appliances Mold , Plastic injection molding, etc.

• In short, we are both a professional mold maker and molder for the series of production for your plastic parts in Taiwan.

• We provide our customers with molds in good quality, and also provide them complete customer services!

FAQ

1. Besides molds, do you generate products as well?

Yes, we can make your projects here in our factory, Taiwan for you. But we only make it from making a new mold...then, from above new mold, making parts out of it. We make the production job for our customers in Taiwan. In other words, we do not have any existing mold. In short, we produced customized molds and products but we also provide our customers reverse engineering service.

2. How can I get the quote?

First, we need our customers provide their technical data like 2D, 3D drawings or samples. After receiving your project, our experienced and professional team will start to study and evaluate it. During this time, our team will keep discussing with the designers to make sure that every details are clear. Finally, we will give our customers quotation reports.

3. Does your company provide design service?

Absolutely yes. We have helped countless customers from Europe and North American to invent their new products. Our experienced engineers give our customers useful suggestion to help them solve the problems that they encounter when designing and process the molds and products.

4. Why is your price so competitive?

First of all, what we are famous for is that we produce interchangeable core mold, which needs not only precision work but also flexible team work to adjust to what our clients really want. Also, all of our steel is from Japan and Germany and all processing steps are carried in Taiwan under the supervision of our professional engineers. We appreciate that all of our customers emphasized on quality and efficiency and that's why our company wants provide too.

To know us more please contact us with your ideas / projects / drawings, so that we can start our studying / engineering job...

To know us more, please visit

www.taiwanmoldmaker.com; www.intertech.net.tw

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.